From Italy to the world

From the production of the first closures in the Piedmont region to present day markets around the world, ours is a story of continuous innovation, team spirit and passion. This mix has allowed us to become leaders in our industry and to invent unique closures and solutions.

Today, we are a growing global Group, able to innovate while respecting the commitment to social responsibility and sustainability. We always aim towards the future.

Years 2020 / Today

Guala Closures S.p.A., a sole shareholder company held by Special Packaging Solutions Investments S.à.r.l. (an independently managed investment subsidiary of Investindustrial VII L.P.) currently has more than 200 intellectual properties. Our global leadership in the sector, and presence in over 100 countries, is able to meet the local production needs of customers

The new plant in Scotland is built and inaugurated. The state-of-the-art sustainable plant reinforces Guala Closures' commitment to the UK market, in particular to the Scotch whisky industry.

Guala Closures inaugurates the opening of its new facility in Nigeria, marking a key milestone in strengthening Africa’s strategic relevance for sustainable, long-term growth

Guala Closures enters the crown closures market thanks to the acquisition of Astir Vitogiannis. Guala Closures consolidates its presence in glass bottles by entering the crown closures sector, strengthening its market position in mineral water and non-alcoholic beverages and expanding into the beer market.

Acquisition of majority stake in Yibin Fengyi Packaging Co., one of the leading closures and boxes manufacturers in China operating within the high-end Baijiu market, the most reputable Chinese traditional liquor market

Definition of a new sustainability program “Sustainable Together 2030”, with specific targets for environmental, social and governance indicators

Acquisition of Labrenta S.r.l., a Vicenza based company specializing in high-end closures, to strengthen the strategic positioning in the luxury segment

Adherence to the United Nations Global Compact, to underline the company's commitment to implement the 10 fundamental principles relating to human rights, labour law, environmental standards and the fight against corruption

Introduction of the Diversity and Inclusion (D&I) Charter to support the elimination of all forms of discrimination in employment practices, both in recruitment and in the workplace

Guala Closures Deutschland is born, which strengthens the Group's presence in the sector supplying closures to the water market. A range of sustainable closures (Blossom Sustainable Closures) is launched, the result of the application of eco-design guidelines and the development of the partnership with Oceanworks®, for the supply of recycled plastic deriving from waste recovered from the oceans

The “No Glue System” implements several technologies to assemble the T-Bar head-stem components without the use of artificial glues. It is a sustainable and environmentally friendly technique that guarantees and preserves the product by preventing the two components from breaking.

The 2010s

Guala Closures expands its presence in international closure markets and introduces the Corporate Social Responsibility program, reinforcing the commitment to develop a sustainable growth model

New listing at the MTA (Mercato Telematico Azionario Borsa Italiana)

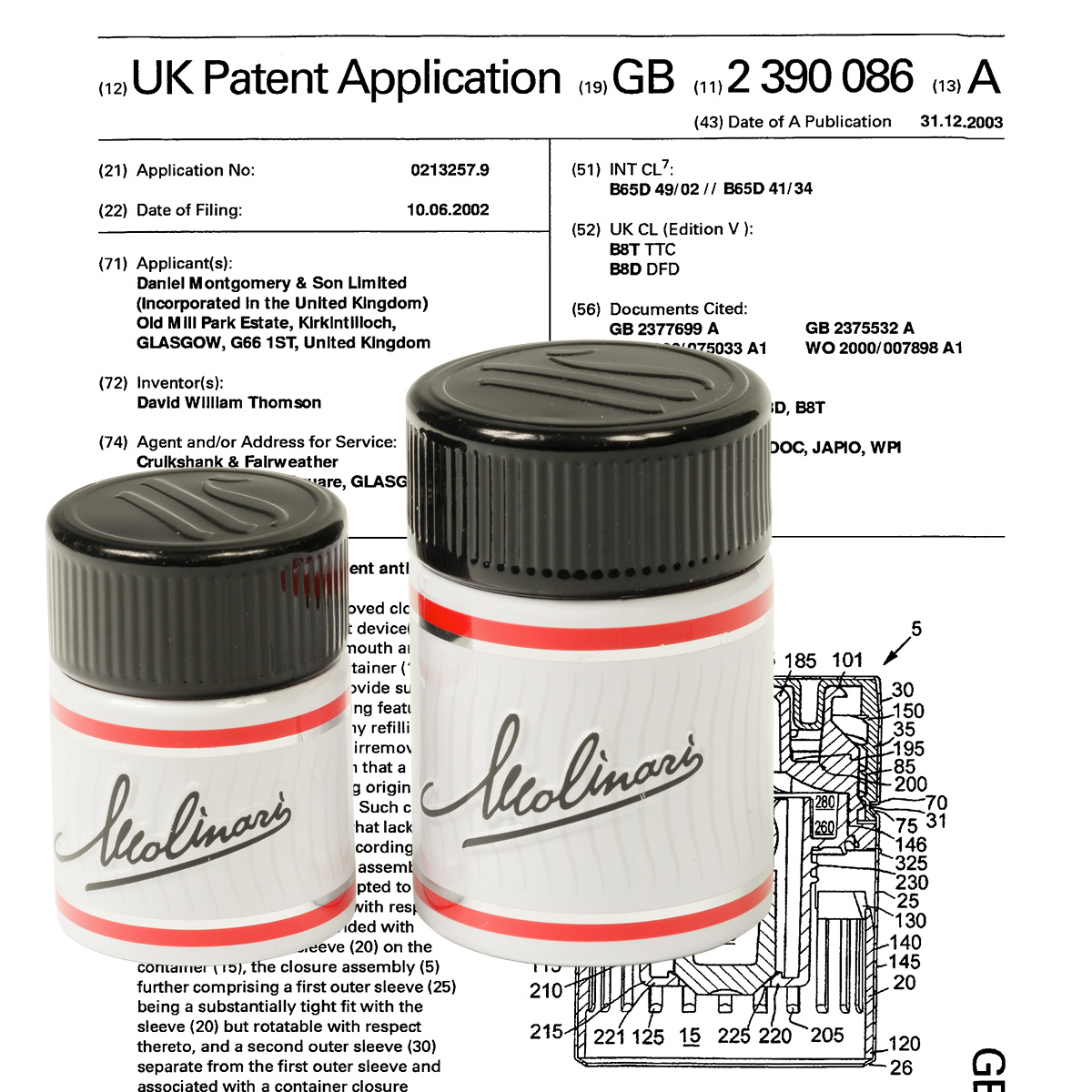

Establishment of the new company Guala Closures East Africa Limited (Kenya) and acquisition of United Closures and Plastics (UCP) in Scotland

Guala Closures South Africa is established

Guala Closures launches its Corporate Social Responsibility (CSR) program and acquires Metalprint in Magenta (Italy), a company specialized in lithography on flat aluminium plates

Guala Closures Bulgaria and Guala Closures DGS Poland are born

The Savin® screwcap for wine combines elegance and a unique, highly customisable design, representing the third evolution in our aluminium roll-on closure series. This latest model significantly expands packaging options for wine producers, offering enhanced flexibility to meet diverse brand positioning and market requirements.

The "Monaco" closure represents the very first tamper-evident solution developed for the t-bar world of closures.

The model features Tamper Evident (TE) closure and a long skirt. It is opened by unscrewing, which leads to the breaking of the weakening line. Once opened, the upper part of the closure is a T-Bar, made of plastic and natural cork.

GreenCap is a fully removable roll-on closure designed for wine & spirits that enables complete separation of aluminium and glass components after use. This sustainable solution facilitates proper recycling by eliminating material cross-contamination, supporting circular economy principles and meeting growing demand for environmentally responsible packaging.

"Verso" is a patented and innovative system designed to guarantee a completely new experience when using the product, with perfect pouring and dripping control. The "Verso" system is comprised of an aluminium screwcap and by a nozzle which “jumps out” every time it is used and retracts back into the bottle when the cap is reapplied.

It features an anti-drip system, to avoid dripping that could occur when the pouring of the liquid is interrupted.

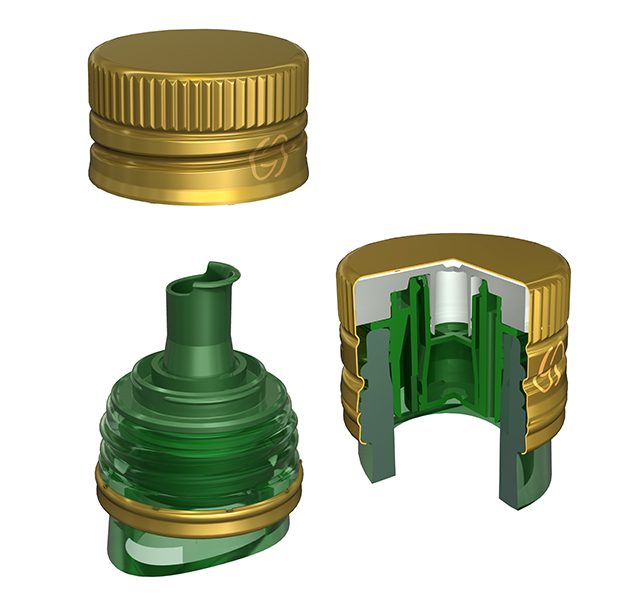

The 1331 model was the first—and still the only one—closure to use bi-injection technology combined with bi-component adhesive, completely eliminating any possibility of reuse or reconstruction of its parts. The result is a closure that is extremely difficult to replicate, offering not only a high level of security but also a distinctive tactile and visual experience.

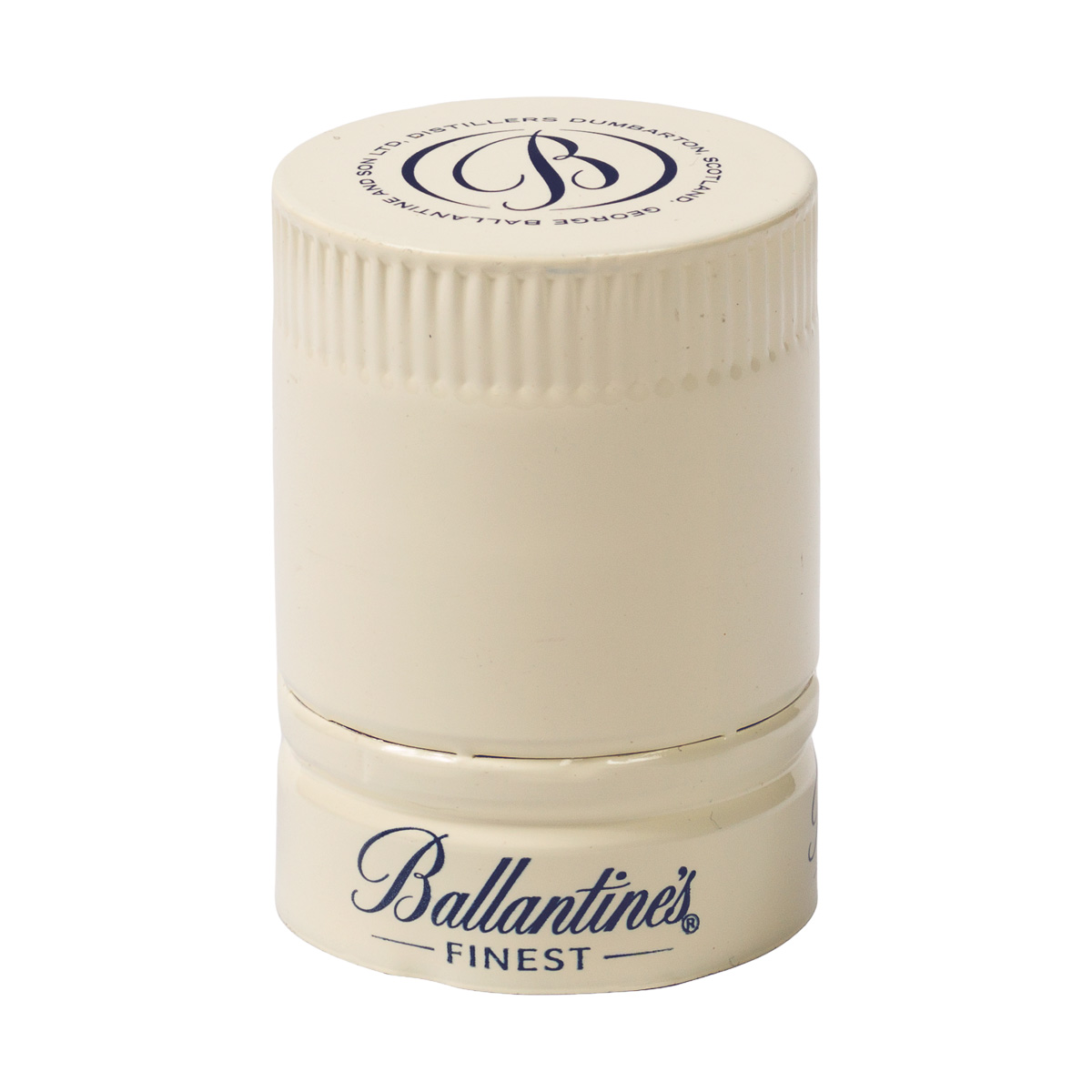

The 631 closure, followed by the Florence model, represents an innovative modular solution that integrates an aluminium overcap, NR cap, and pourer with single valve technology. Specifically developed for Ballantine's whisky, this invention underscores the historic bond between the brand and Guala Closures: notably, this prestigious producer has been Guala Closures client since 1966, demonstrating a long-standing partnership that continues to drive cutting-edge technological solutions.

The 90s/2000s

Numerous initiatives are undertaken in the 90s, both in the production field, with the opening of the plant in Termoli, and in the social field. In 1998, the Guala family leaves the company and the Guala Closures Group is officially established.

With the beginning of the new millennium, new products are launched (consolidating the innovative DNA within the Group) and the path of international growth continues.

Guala Closures Technology Ukraine, based in Sumy (Ukraine), is founded

Inauguration of the new headquarters and production plant in Spinetta Marengo (Alessandria, Italy)

Opening of new sales offices in North America and France and new production facilities in New Zealand and Australia

Guala Closures is listed on the Italian stock market and subsequently in its STAR Segment

The Aluminium Division is born and Global Cap S.p.A. is acquired

The Guala Closures Group is born

The WAK® closure seamlessly blends the classic silhouette of a traditional wine bottle with the advanced functionality of an aluminium screw cap, offering both elegance and modern convenience. What sets this model apart is its integration of NFC (Near Field Communication) technology, allowing for interactive consumer engagement, product authentication, and enhanced traceability—bringing innovation directly into the hands of the user while preserving the heritage of wine packaging.

The patented AluSnap closure features a non-refillable system with premium aluminium casing available in multiple sizes. This innovative closure reflects the market evolution since the late 1990s toward solutions that combine advanced safety technology with superior aesthetics. Aluminium's premium positioning and exceptional decorative capabilities allow for comprehensive customization across the entire closure structure. The J&B brand was among the first to adopt this innovative closure solution.

Designed specifically for the Indian market, where spirit adulteration is widespread and fast, high-volume production is essential, this guarantee closure—known as the "Nip Cap"—features just two plastic components. Tailored for small bottles, it offers a quick, simple, and cost-effective yet secure solution. The consumer opens it by removing a distinctive tear band, which makes any tampering immediately visible once broken.

The 1500 model features a technopolymer skirt anchored to the bottle and ultrasonically welded to the internal components, with a patented seal band that stays attached to the cap after opening. Its guarantee system evolves from a single valve to a more advanced mechanism with two glass balls and a plastic valve for enhanced security. Originally developed from an internal idea rather than a client request, this innovative closure was first adopted by J&B, showcasing Guala Closures’ proactive approach to design and protection.

This early high-security, anti-counterfeiting closure was first developed for the Chinese market, initially created for Martell cognac and later adapted for Mexico. It features a non-refillable system with a long outer cap covering most of the closure. When opened, a plastic tear-off band destroys the aluminum, preventing reuse. For added protection against tampering, the pourer is ultrasonic-welded to a technopolymer skirt, ensuring a robust, non-removable structure.

The 70s/80s

Guala continues to grow internationally and to launch several ranges of products, some of which are very complex and able to offer increasingly sophisticated protection features. This is when the concept of a cap as an aesthetic element, as well as a protection, is born. This aspect, added to the design quality and timeliness of realization, proves to be a winning formula on the market.

This innovative closure model, developed through a strategic acquisition, is designed for glass water bottles with a three-component construction. The aluminium cap provides premium aesthetics and durability, while the PE liner ensures reliable sealing at the bottle mouth. The plastic ring incorporates Tamper Evident technology through breakable jumpers that visibly break when opened, providing clear indication that the closure has been tampered, ensuring product integrity and consumer confidence.

Launched in 1978, the patented 1031 model marked a turning point in closure design with its simplified structure and pressure-fit anchoring system, which reduced plastic use. Combining aesthetics and functionality, it featured a secure locking mechanism that tightly gripped the bottle neck to prevent removal. Composed of just 4–5 parts, the closure allowed for fast assembly and came in three heights and three versions: open pour, protected pour, and valve pour. Its side surface offered ample space for decoration, often eliminating the need for a neck label—highlighting how design and visual appeal became as important as tamper evidence.

The 560 model, created for the Buton distillery’s flagship product Vecchia Romagna, is a non-refillable closure similar to the 550 but with a larger diameter. It includes a soft silicone rubber gasket for optimal sealing on glass bottle necks. The closure is opened by breaking an aluminum band with an integrated guarantee tab marked "Buton Italia – Fascia di garanzia," ensuring authenticity and security.

The 339 model, developed for long-time client Olio Sasso, is a two-piece closure featuring a polyethylene pourer. It includes a tamper-evident tear-off band that must be removed to open the bottle, ensuring product integrity.

The 50s/60s

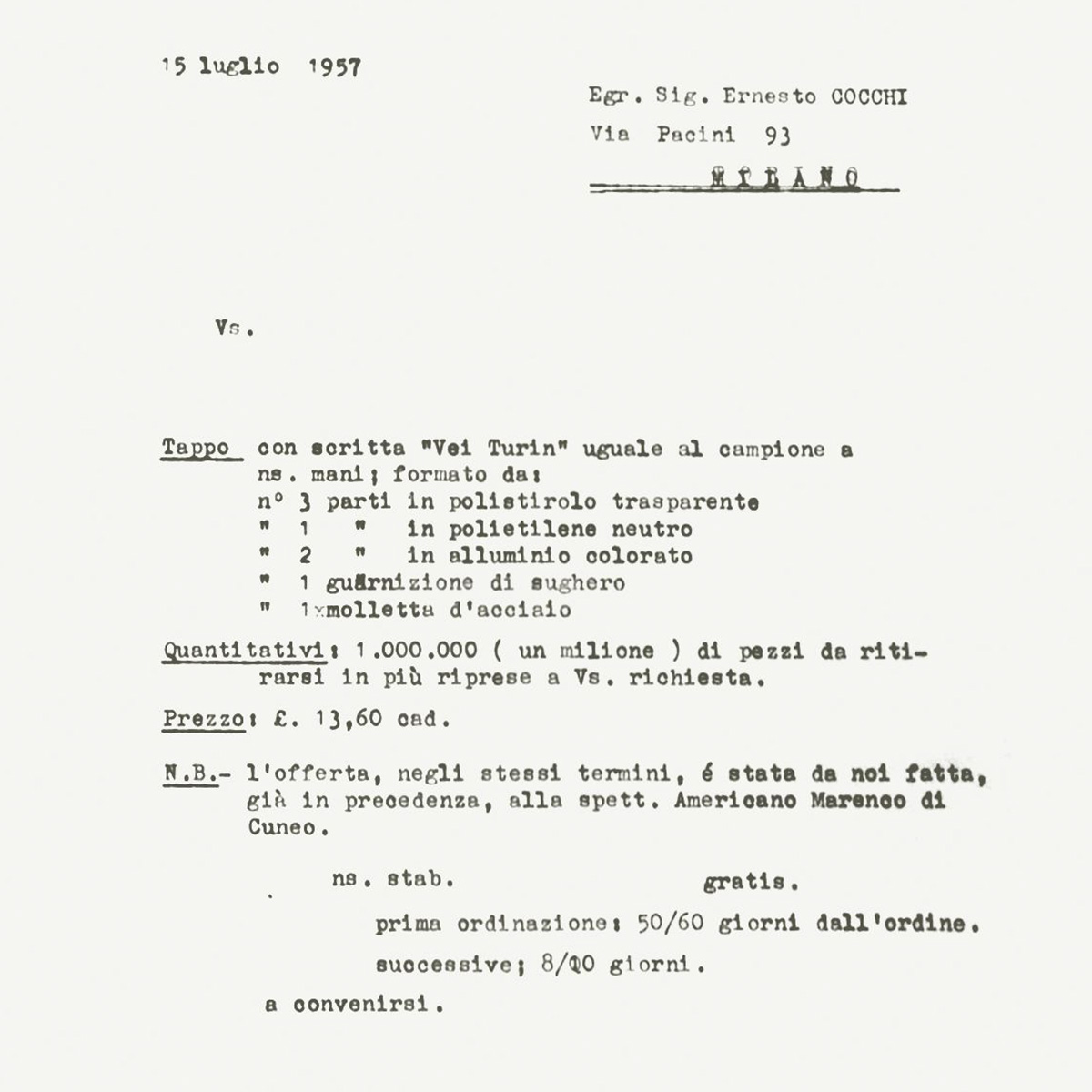

In 1954, the adventure began in Alessandria, from an idea of Angelo Guala: to create and devise new products to bring to the market, with strong customer involvement, reworking new plastic materials.

In the midst of the Italian economic miracle, Guala takes off: the innovative "warranty closure" is launched, able to protect the product thanks to its non-refillability feature, and the first patented non-refillable closure models are produced. In addition, the first steps are taken outside the national borders, with initial supplies, destined for Scotland's whisky and spirits market.

The 550 model, one of Guala Closures’ first iconic products for alcoholic beverages, was designed with a focus on security and functionality. It featured a non-refillable mechanism, a tamper-evident seal to ensure product authenticity, a drip-saving side-pour system, and a silicone rubber gasket for a perfect fit on glass necks. The closure was secured with a rolled aluminum ring and opened by unscrewing, breaking the plastic guarantee bridges.

Introduction of the first tamper-evident closures, appreciated by liquor manufacturers and recognized by the market for their reliability in preventing refilling fraud.

In 1959, the first patent for safety closures was filed.